At McGeoch Defence Systems, we understand the challenges of maintaining operational efficiency in naval fleets reliant on ageing equipment. Additionally, obsolete parts can derail missions, increase downtime, and escalate costs, especially when replacements are no longer available. Furthermore, with naval obsolescence management solutions, McGeoch ensures that fleets overcome these obstacles, extending the life of older vessels while keeping them mission-ready.

This blog explores the importance of obsolescence management and highlights,

How McGeoch’s tailored solutions help naval fleets stay operational

1. The Challenge of Naval Obsolescence

Firstly, obsolescence is an inevitable issue for naval fleets operating with ageing systems. Furthermore, as original parts are discontinued, sourcing replacements becomes a major challenge. This can lead to:

- Downtime: Extended delays while trying to procure rare components.

- Higher Costs: Premiums for outdated or hard-to-source parts.

- Decreased Efficiency: Older, worn-out components reduce system performance.

Modern naval operations depend on proactive management to ensure that obsolete components don’t compromise mission-critical capabilities.

2. McGeoch’s Naval Obsolescence Management Solutions

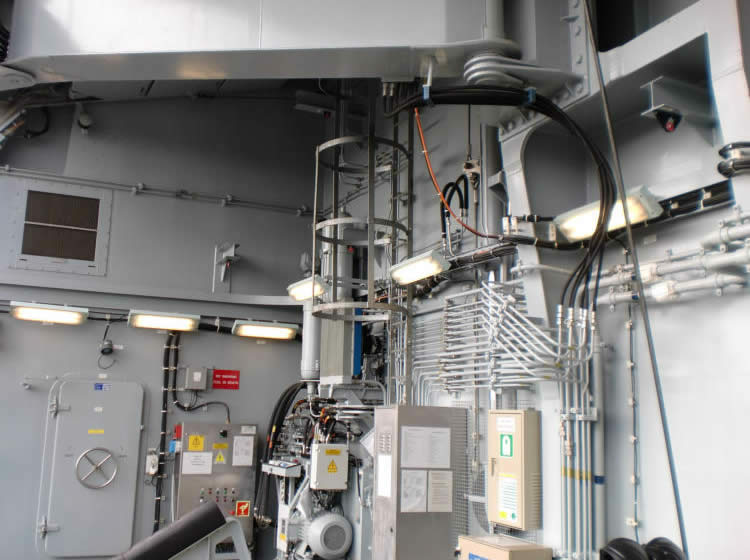

At McGeoch, we provide innovative solutions to tackle obsolescence head-on. Additionally, by focusing on reverse engineering, custom manufacturing, and compatibility, we enable fleets to maintain operational continuity without overhauling entire systems.

How McGeoch Addresses Obsolescence:

- Reverse Engineering: We replicate obsolete parts using precise specifications, ensuring seamless functionality with existing systems.

- Custom Manufacturing: When critical components are no longer available, McGeoch produces high-quality replacements tailored to your needs.

- System Compatibility: Our solutions integrate seamlessly with ageing systems, avoiding costly upgrades or retrofitting.

With these approaches, our naval obsolescence management solutions reduce downtime and keep vessels operational.

3. Reverse-Engineered Naval Spares: A Lifeline for Ageing Fleets

Reverse engineering is a cornerstone of effective obsolescence management. Also, by recreating components that are no longer in production, we ensure fleets have access to the spares they need.

Why Reverse-Engineered Spares Matter:

- Precision Replication: Our techniques ensure that new parts meet or exceed the performance of the originals.

- Cost Efficiency: Avoid expensive system overhauls by replacing only the necessary components.

- Extended Lifespan: Reverse-engineered spares breathe new life into ageing systems, reducing the need for decommissioning.

McGeoch’s reverse-engineered naval spares are a reliable, cost-effective solution to obsolescence challenges.

4. Planned Obsolescence Management: A Proactive Approach

Preventative strategies are essential to avoid the high costs and disruptions caused by sudden obsolescence. Subsequently, McGeoch’s planned obsolescence management solutions help fleets anticipate and address potential issues before they arise.

Key Strategies:

- Inventory Audits: We review components to identify those nearing obsolescence.

- Lifecycle Analysis: By understanding the lifespan of existing parts, we provide recommendations for timely replacements.

- Forecasting Needs: Our proactive approach ensures necessary spares are manufactured ahead of time.

Planned obsolescence management reduces the risk of equipment failures, enabling smooth and uninterrupted operations.

5. Long-Term Benefits of Managing Obsolete Naval Parts

Effective obsolescence management brings significant advantages to naval fleets. In addition, by partnering with McGeoch, military organisations can achieve:

Key Benefits:

- Cost Savings: Avoid expensive upgrades or replacements by sourcing reverse-engineered parts.

- Reliability: Keep ageing systems operational at optimal levels.

- Operational Continuity: Prevent mission disruptions caused by part shortages or failures.

McGeoch’s solutions ensure that older vessels remain assets, not liabilities, for modern naval operations.

FAQs

What is obsolescence management for naval fleets?

Obsolescence management involves strategies to maintain operational efficiency when parts become unavailable, including reverse engineering and custom manufacturing.

How does reverse engineering help with obsolescence management?

Reverse engineering replicates discontinued components, ensuring that systems remain functional without requiring costly upgrades or replacements.

Can McGeoch manufacture custom parts for ageing vessels?

Yes, McGeoch specialises in custom-manufactured marine components, ensuring compatibility and reliability for older naval systems.

The Importance of Naval Obsolescence Management Solutions

In conclusion, obsolescence is a challenge every naval fleet must face, but with McGeoch’s naval obsolescence management solutions, ageing systems can continue to perform reliably. Moreover, from reverse-engineered spares to proactive obsolescence strategies, our solutions ensure mission readiness while controlling costs.

Contact McGeoch Defence Systems today to learn how we can help your fleet navigate the challenges of obsolescence with confidence.